Why a Reliable Air Cooled Hydraulic Oil Cooler Makes a Real Difference in Mobile Machinery

If you spend enough time around construction machinery, agricultural equipment, or any machine that runs hydraulics for hours on end, you already know how big a role temperature plays. When the system gets too hot, everything feels slower. Pumps strain, valves don’t respond the way you expect, and the whole machine just seems tired. That’s exactly why a dependable air cooled hydraulic oil cooler isn’t a luxury—it’s something most operators genuinely rely on every single day.

At YUDA, we’ve seen how well-designed cooling solutions reshape the long-term performance of a machine. And while there are countless cooling options out there, the combination of an air cooled hydraulic oil cooler, stable advanced hydraulic cooling systems, and a durable air cooled hydraulic heat exchanger consistently proves to be one of the most practical setups for real working environments.

The Everyday Heat Problems Operators Face

Hydraulic systems always generate heat—some days more than others. Long work hours, high-pressure cycles, and heavy loads can push the system right to the edge. If the heat has nowhere to go, the hydraulic oil starts losing viscosity, and suddenly the machine feels unresponsive. We hear this complaint a lot, especially from operators working under the sun or in tight work cycles.

That’s where an air cooled hydraulic oil cooler steps in. Its job sounds simple—pull heat away and stabilize oil temperature—but when you place it side by side with advanced hydraulic cooling systems, it becomes clear just how central it is to system reliability. Pair that with a rugged air cooled hydraulic heat exchanger, and the cooling process becomes something operators no longer have to worry about.

Why the Air Cooled Hydraulic Oil Cooler Works So Well

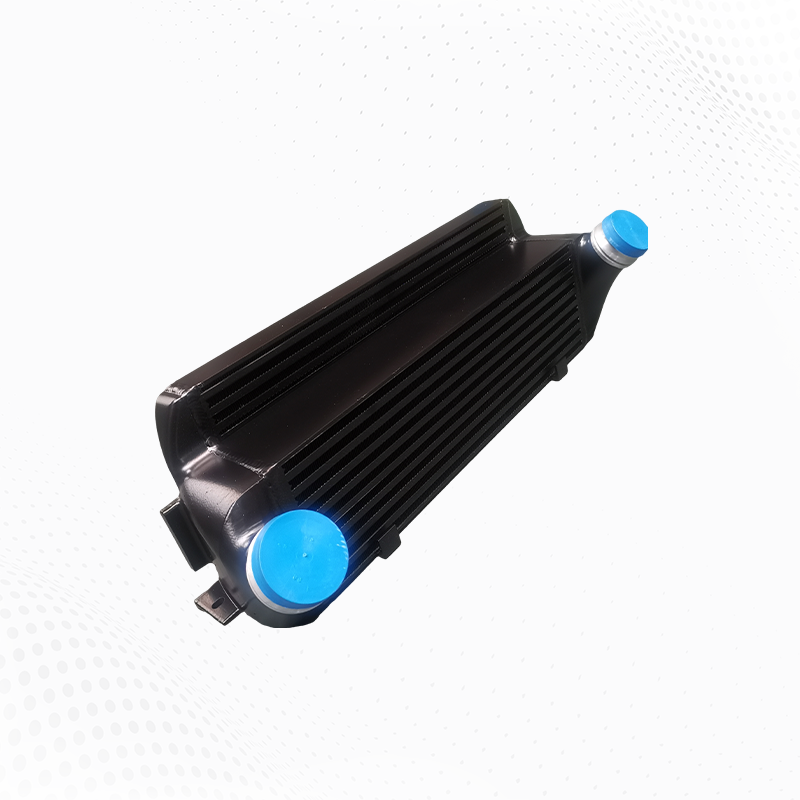

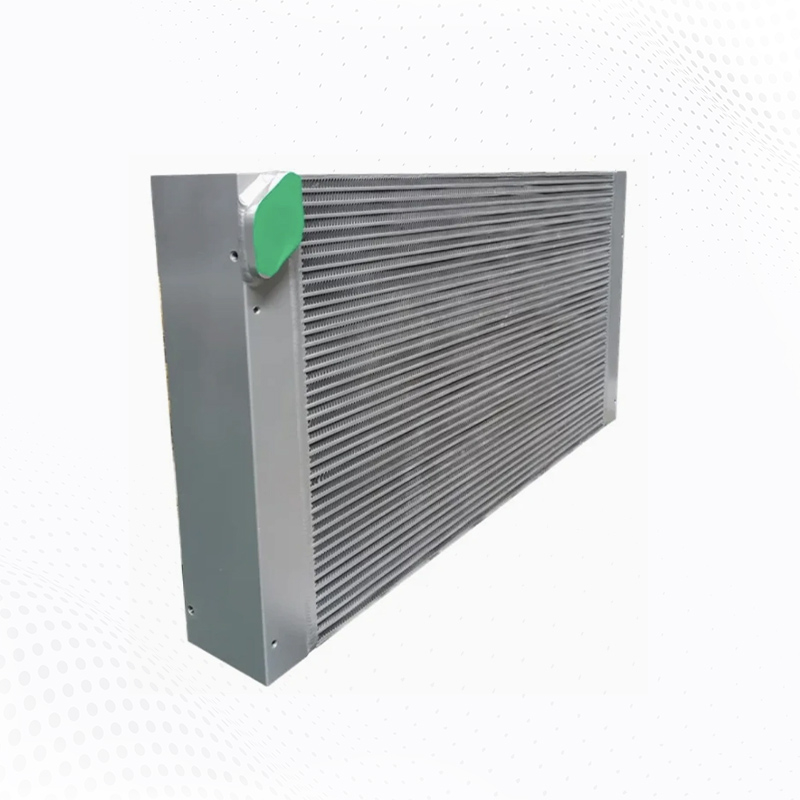

One of the biggest reasons people like using an air cooled hydraulic oil cooler is the simplicity. No water pumps, no extra plumbing, no need to worry about the availability of clean cooling water. Instead, the system uses airflow and a sturdy aluminum core to move heat away quickly and consistently.

This simple geometry makes the air cooled hydraulic heat exchanger incredibly useful for mobile or remote machinery. You get dependable cooling without complicated hardware, and the system fits easily into many types of advanced hydraulic cooling systems. It doesn’t demand ideal conditions. It just works.

And because most mobile machines operate in dusty, bumpy, unpredictable environments, an air cooled hydraulic oil cooler becomes even more attractive—it tolerates these conditions far better than many alternatives.

What Operators Usually Notice First

Based on years of working with OEMs and field technicians, there are a few improvements that show up almost immediately after upgrading to an air cooled hydraulic oil cooler:

1. Much More Stable Operation

Hydraulic pressure stays more consistent when the oil temperature doesn’t bounce around. A solid air cooled hydraulic oil cooler helps maintain that stability, especially when integrated into advanced hydraulic cooling systems. Paired with a good air cooled hydraulic heat exchanger, the whole machine feels smoother during long shifts.

2. Less Maintenance

No water leaks. No corroded lines. No dealing with unexpected mineral deposits. The simplicity of the air cooled hydraulic heat exchanger reduces the number of things that can go wrong. And the fewer things that can go wrong, the fewer repair breaks operators have to deal with.

3. Longer Component Life

Most hydraulic failures are heat-related. Once the oil stays within a healthy temperature range—thanks to a reliable air cooled hydraulic oil cooler—everything else tends to last longer. Pumps, hoses, cylinders, seals—they all benefit from working in a stable thermal environment supported by advanced hydraulic cooling systems.

Built for the Places Machines Actually Work

Cooling systems designed for labs or ideal conditions don’t survive long in a real job site. That’s one of the main reasons YUDA puts so much effort into durability.

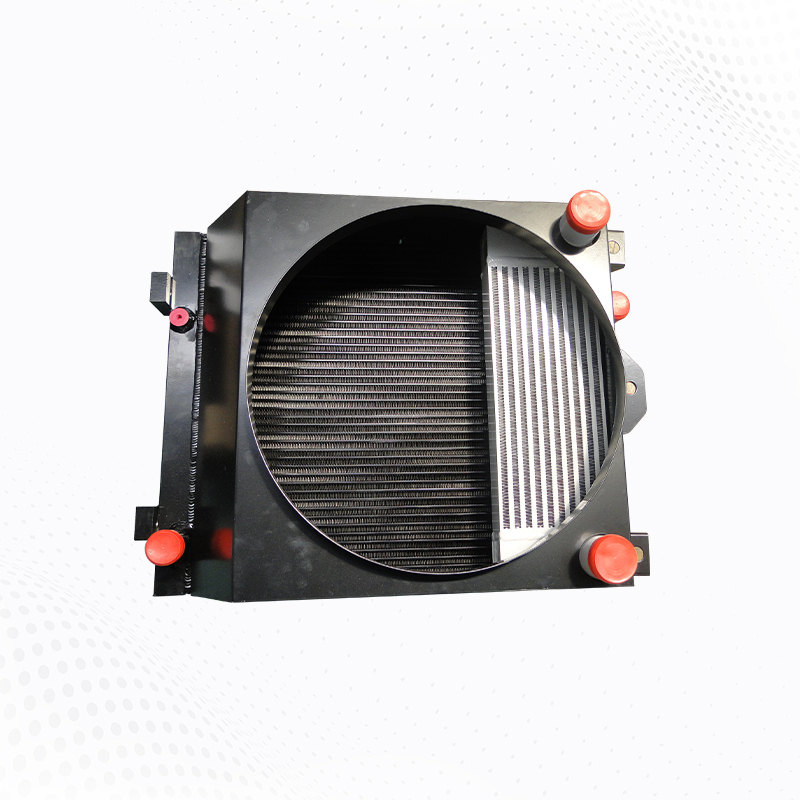

The aluminum structure of our air cooled hydraulic oil cooler isn’t just lightweight—it's strong enough to handle vibration, uneven surfaces, and sudden load changes. The fans built into our air cooled hydraulic heat exchanger are selected specifically for dusty and hot environments. And when these components come together inside advanced hydraulic cooling systems, the setup works reliably even after hours of strain.

We design coolers for places where engines roar, materials slam, and dust never settles. That’s the real world our customers operate in.

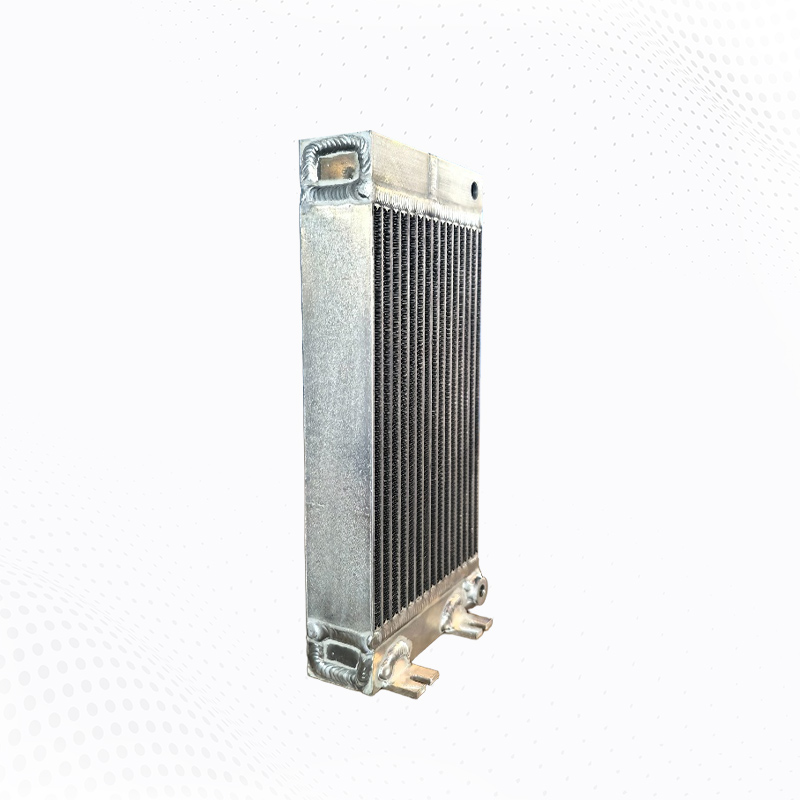

Why Energy Efficiency Matters More Than Before

Fuel prices never seem to go down. That’s why energy efficiency has become a major topic for fleet managers and equipment owners. One of the understated benefits of a well-designed air cooled hydraulic oil cooler is that it reduces the thermal load on the machine without adding unnecessary resistance or complexity.

When the air cooled hydraulic heat exchanger moves heat efficiently, the system breathes a little easier. There’s less stress on the hydraulics, and advanced hydraulic cooling systems can maintain performance without burning extra energy. It’s the kind of improvement that looks small on paper but shows up clearly in long-term operating costs.

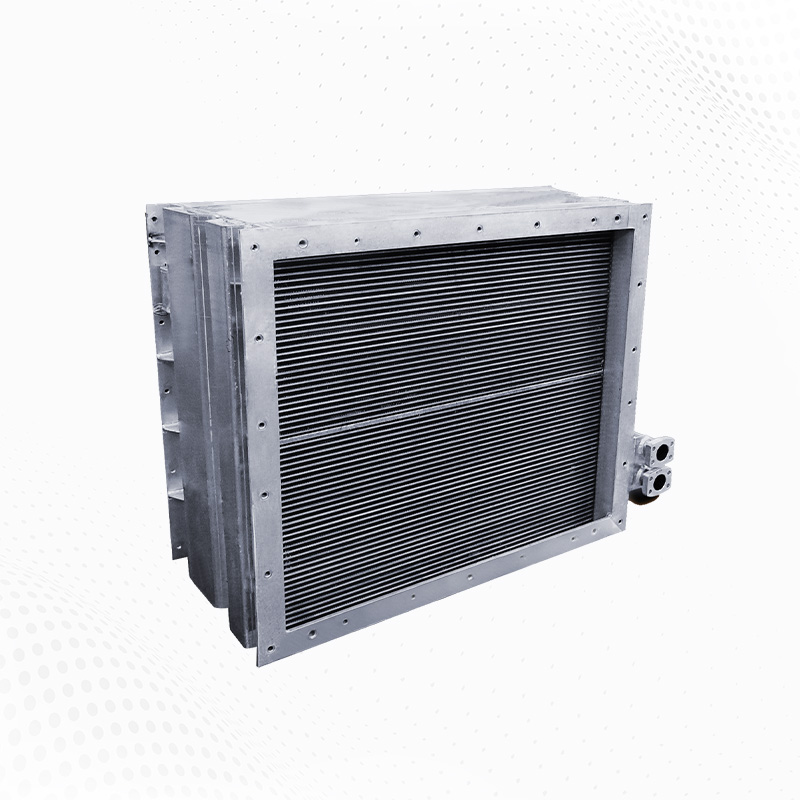

Easy Integration Across Different Machine Types

Because every machine has its limits—space, weight, airflow—flexibility matters. A good air cooled hydraulic oil cooler must adapt to those limits without compromising performance. That’s why YUDA builds multiple configurations, fan options, and mounting choices.

Whether it’s an excavator, loader, harvester, crane, or road machine, the cooler fits naturally into advanced hydraulic cooling systems. And since the air cooled hydraulic heat exchanger comes in different sizes and capacities, it can be matched precisely to each machine’s duty cycle.

This adaptability is one reason many manufacturers keep coming back to the same cooling structure—it just makes integration easier.

A Cooling Solution That Feels Practical, Not Complicated

The best designs are the ones that make the operator’s life simpler, not harder. And that’s ultimately the value of a dependable air cooled hydraulic oil cooler. When supported by advanced hydraulic cooling systems and strengthened with a durable air cooled hydraulic heat exchanger, the cooling setup becomes something operators can trust without thinking about it every day.

Fewer breakdowns. Fewer temperature alarms. Fewer reasons for the machine to go offline in the middle of a job.

For most operators, that’s exactly what they need.